Manufacturing integration

mpVision for GxP

Validating deep learning models in pharmaceutical manufacturing, or any highly regulated industry, involves several critical steps to ensure the models are reliable, accurate, and compliant with regulatory standards. mpVision demonstrates that its models are fit-for-use and perform as intended, are generalizable to real-world data, and meet the specific KPIs of the manufacturing environment.

Integrate your AI models into your manufacturing process with mpVision — a GxP-compatible image processing platform that enables you to generate, validate, integrate, and continuously monitor your model's performance in your manufacturing process.

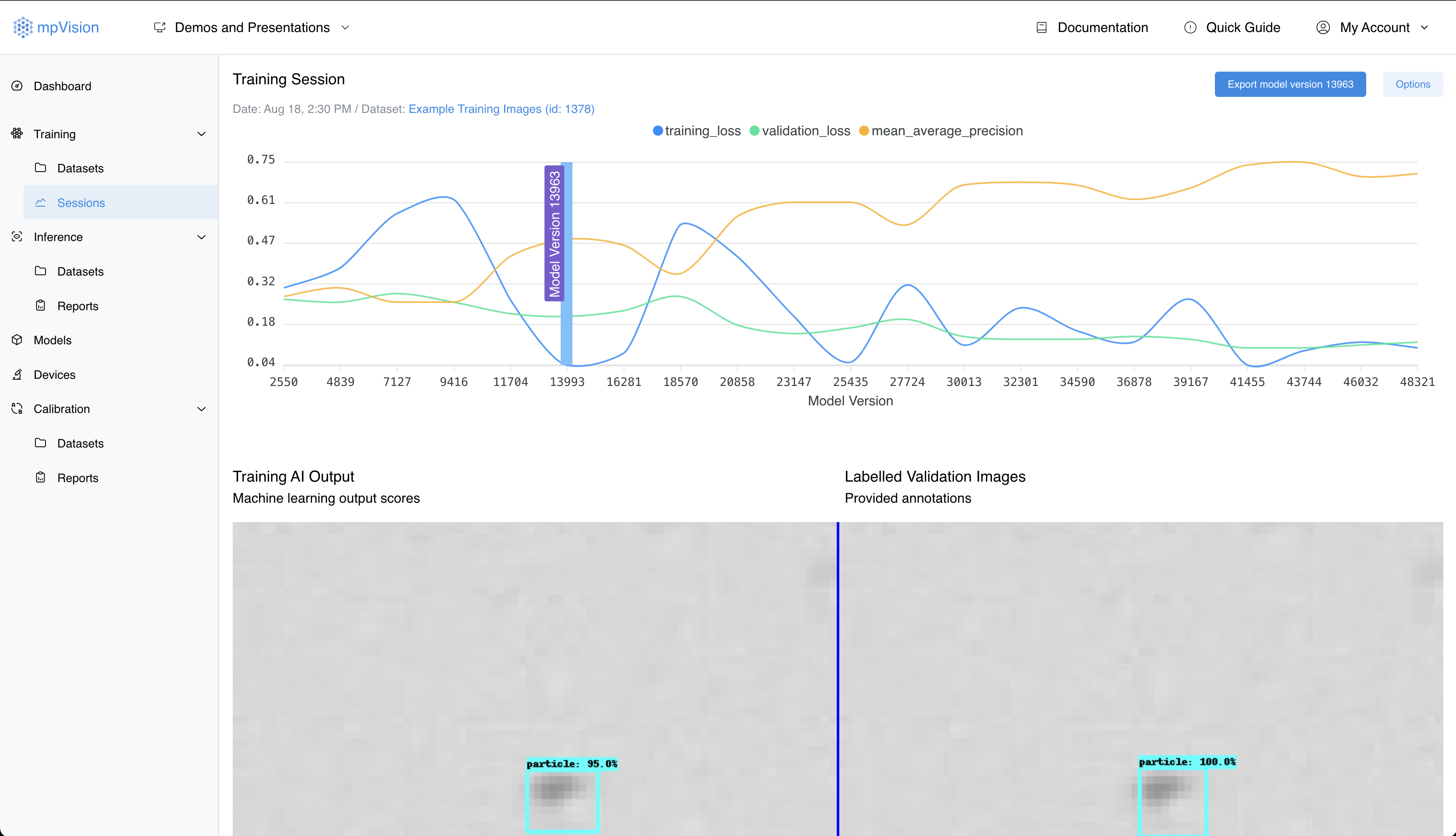

Train and Evaluate Models

Models are trained in-house on your own image data. The models are then validated in-line, and their performance is tested before deployment. The performance metrics (e.g. accuracy, precision, recall, and confidence) are selected based on the specific application in the manufacturing process.

- Monitor training

- Validate metrics

- Adjust parameters

- Control versions

Easily document the model development process, data handling procedures, validation methods, and performance results. Trace model versions and changes while ensuring the model is compliant with your quality standards.

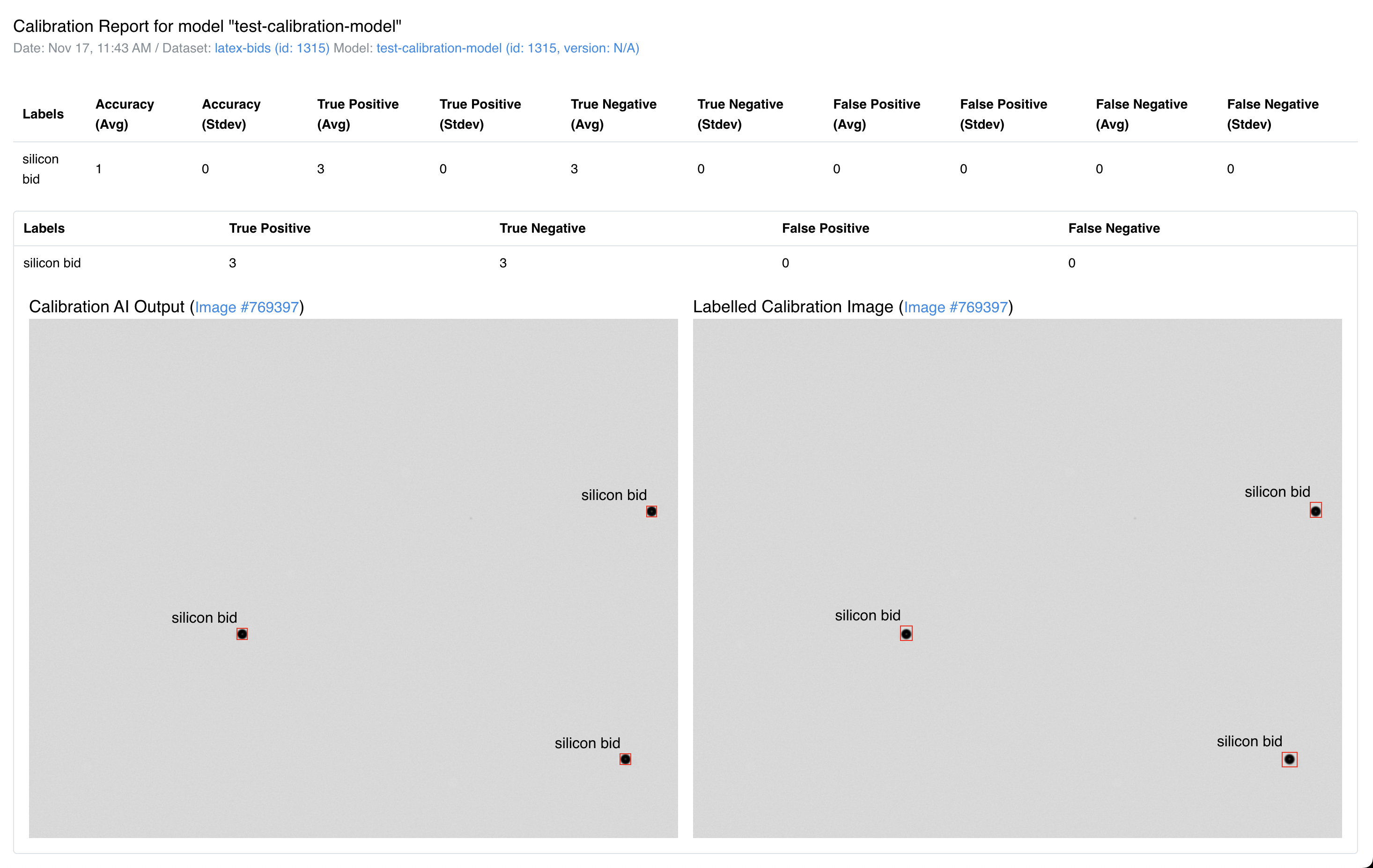

Benchmark Performance

Test your model's performance against predefined criteria and requirements. Input test images and compare model performance to existing systems or human performance to ensure it meets or exceeds the required standards. The performance metrics are selected based on the model's intended use in the manufacturing process.

- Upload production test images

- Specify expected output and performance metrics

- Generate reports and compare to existing systems

- Approve deployment or reinitiate model training

Connect to Camera Equipped Devices

Integrate your devices with mpVision to start monitoring your manufacturing process.

Secure access to models

- Connect to imaging devices and access your models securely from anywhere in the world. Our API with the latest security protocols ensures your data is safe. Any site of your organization can connect to deployed models.

High processing speed

- mpVision scales compute power to achieve real-time processing speed. This capacity enables your manufacturing process to be monitored without interruption. Robust and well-tested infrastructure ensures software availability at any time.

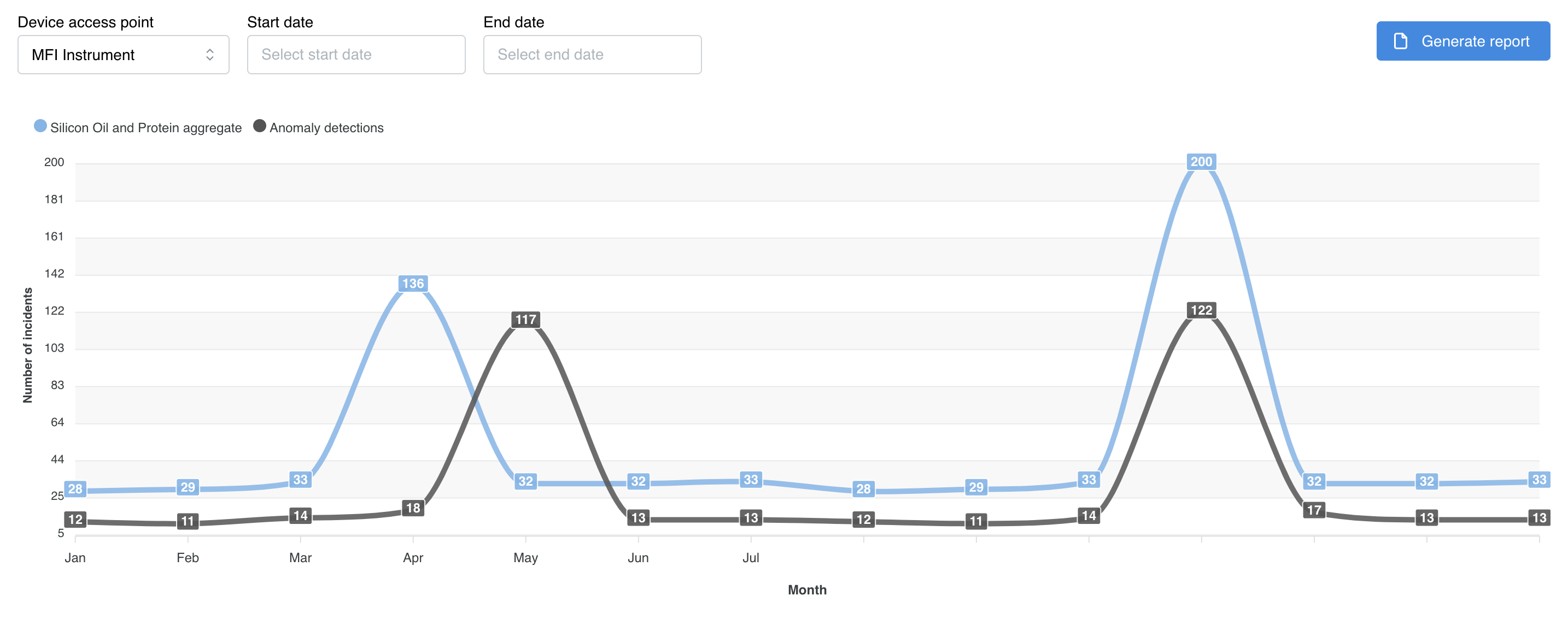

Continuously Monitor and Revalidate Models

Whether you are monitoring for contaminations, particulates, or morphologies, mpVision provides you with the tools to configure alert systems and validate your models based on your preferred setup.

- Previous

- Overview

- Next

- Get started